No Products in the Cart

Click Here to Schedule a FREE Consultation

Phone: 866-943-6887 Email: sales@safetyinstruct.com

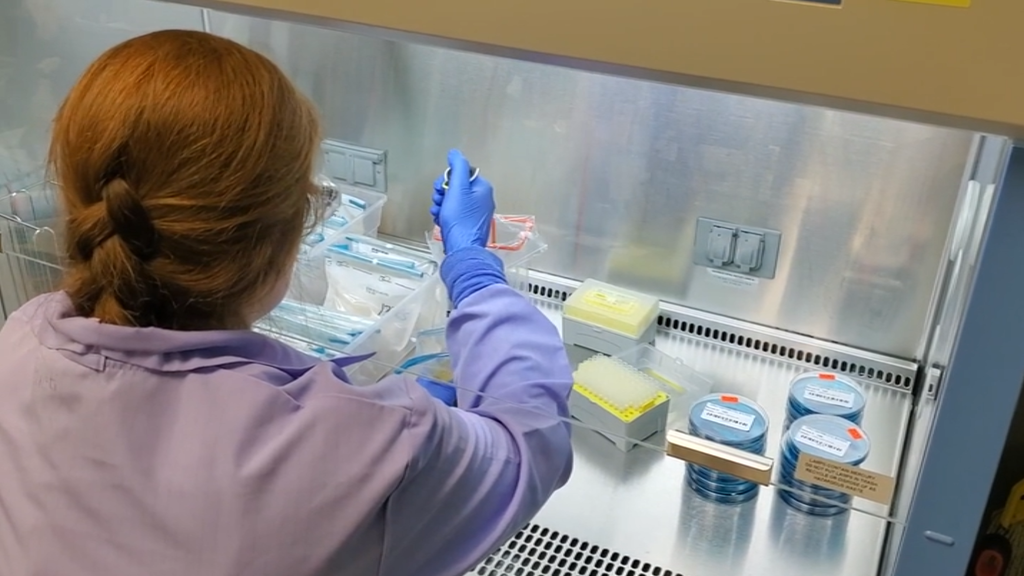

During any laboratory testing, sanitation is a critical component to ensuring the accuracy of the results you are wanting to achieve. All the equipment used must be properly sterilized and cleaned prior to any new applications. This is achieved through a piece of equipment called an autoclave. It combines pressure and steam to reach the temperatures necessary to kill and remove any biological agents that may still be on the equipment. Autoclaves are a common sight in most laboratories, but still have associated hazards and warnings. The awareness of how to properly set up, manage and maintain an autoclave is critical to working safely.

Autoclave Operation

An autoclave’s primary purpose is to sterilize equipment of any living organisms that may be present. It achieves this through hot, pressured steam. Typically, the items sterilized include glassware, instruments, media, solutions and biohazardous waste.

Risks & Exposures

With any piece of equipment, incidents can happen. During use with an autoclave, there are several types of possible exposures. However, most incidents occur when opening the autoclave after a cycle has finished.

Incident Prevention

Preventing incidents with autoclaves and sterilizers is paramount in ensuring laboratory safety. Proper operation, regular maintenance, and designated employees responsible for thorough inspections are critical measures to mitigate potential risks and accidents. Understanding the correct procedures for autoclave use, maintenance protocols, and safety checks are essential components for maintaining a secure laboratory environment.